2026 Best Steel Framing Options for Your Next Construction Project?

Steel framing is becoming increasingly popular in construction projects. As we look towards 2026, it’s essential to understand the best options available. Steel framing offers sturdiness and durability, crucial for modern structures. Many builders favor it for its ability to withstand various weather conditions.

However, not all steel framing is created equal. Different materials, coatings, and construction techniques can impact performance. Some options may prove more expensive initially but can lead to long-term savings. It’s also important to weigh factors like labor costs and local availability.

Builders and architects must reflect on their choices. Are they considering the best steel framing for their needs? Conducting thorough research can prevent costly mistakes. As we advance into 2026, being informed about steel framing will set your project apart from the competition.

Overview of Steel Framing Materials and Their Benefits

Steel framing has emerged as a popular choice in construction. It offers strength, durability, and resistance to environmental factors. According to recent industry reports, steel structures can last up to 50 years longer than wood frames. This longevity is a significant benefit that many builders consider today.

Steel framing materials are typically lighter than traditional options. This feature makes transportation and installation easier. Moreover, they are more resistant to pests and rot. The U.S. Department of Energy highlights that steel is 100% recyclable. This quality supports sustainable building practices. Not to mention, steel does not emit harmful chemicals during its lifecycle.

Tip: Always consider local building codes before starting your project. Compliance is essential for structural integrity and safety.

While there are numerous advantages, costs can be higher than wood framing. Builders often need to weigh the long-term benefits against the initial investment. Sometimes, steel can be perceived as cold and uninviting. It’s crucial to think creatively about incorporating warmth and character into steel structures.

Tip: Explore innovative design techniques to soften the appearance of steel. Mix materials to create a balanced aesthetic.

2026 Best Steel Framing Options for Your Next Construction Project

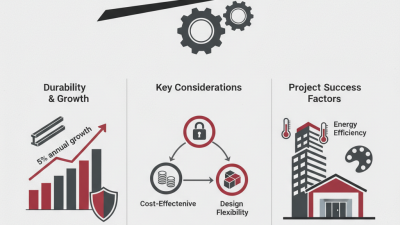

This chart illustrates the advantages of various steel framing materials used in construction projects, focusing on their strength, cost-effectiveness, and sustainability metrics.

Comparing Different Types of Steel Framing Systems

When considering steel framing systems for construction, it's essential to compare the various options.

Structural steel is known for its strength and durability. It works well for large structures. However, it's heavier and may require specialized equipment for installation.

Cold-formed steel framing offers a lighter alternative. It's often easier to transport and work with. This option supports smaller buildings like homes or commercial spaces.

Yet, its strength may be less than that of traditional steel. It's crucial to weigh the pros and cons of each system.

Some projects might see flaws in design or execution when using cold-formed options.

Another noteworthy type is steel stud framing. This system utilizes thin strips of steel. It provides good support for walls and ceilings.

However, some users find it less reliable under high loads. The decision ultimately hinges on project specifications and budget constraints.

Thoughtful planning can prevent future issues and improve the overall outcome.

Key Factors to Consider When Choosing Steel Framing

Choosing the right steel framing for construction can seem daunting. One key factor is the type of steel used. Different grades offer varying strength levels and corrosion resistance. Projects in coastal areas may require more rust-resistant materials. Think about the local climate and environment when deciding on steel specifications.

Another important consideration is the design flexibility steel framing provides. It allows for larger open spaces without compromising stability. This is particularly beneficial for modern architectural designs. However, balancing flexibility with structural integrity can be complex. Builders often need to reflect on load-bearing requirements throughout the project.

Cost is also a critical factor. Steel framing can be more expensive upfront, but it may save money in the long run due to durability. Consider the overall lifecycle costs, including maintenance and potential repairs. Each project has unique needs, requiring careful evaluation to avoid mistakes. Proper planning and choices can lead to a more efficient build and lasting outcomes.

2026 Best Steel Framing Options for Your Next Construction Project - Key Factors to Consider When Choosing Steel Framing

| Framing Type | Weight (lbs/ft) | Cost ($/ft) | Load Capacity (lbs/ft) | Corrosion Resistance | Sustainability Rating |

|---|---|---|---|---|---|

| Light Gauge Steel | 1.2 | $3.50 | 40 | High | A |

| Structural Steel | 2.5 | $5.00 | 100 | Medium | B |

| Cold-Formed Steel | 1.0 | $2.80 | 35 | High | A |

| Heavy Gauge Steel | 3.0 | $6.50 | 150 | Low | C |

| Steel Studs | 1.5 | $4.00 | 45 | Medium | B |

Innovative Steel Framing Techniques and Technologies for 2026

As we look ahead to 2026, innovative steel framing techniques are gaining attention. These methods promise to enhance the durability and sustainability of construction projects. One notable technique is modular steel framing. This method involves pre-fabricating sections offsite. It reduces on-site labor and construction time. Prefabricated components can be assembled quickly, leading to fewer delays.

Another exciting development is the use of lightweight steel. It offers enhanced strength without the bulk. Designers are beginning to experiment with various shapes and sizes. This flexibility allows for unique architectural designs. However, it also presents challenges. Builders must perfect the balance between strength and weight. If not done correctly, structures may face unforeseen issues over time.

Lastly, advancements in steel coatings have improved longevity. These coatings protect against rust and damage. However, their effectiveness depends on proper application. Incomplete or flawed surface preparation can lead to failure. As we embrace these innovations, reflection is essential. What works well today might not be best in the future. Continuous learning and adaptation will pave the way for better construction practices.

Sustainability and Cost-Effectiveness in Steel Framing Solutions

In recent years, steel framing has gained attention for its sustainability benefits and cost-effectiveness. Steel is recyclable and often made from recycled materials. This reduces the demand for raw resources. Using steel can lower the carbon footprint of a construction project. As environmental concerns grow, this factor becomes crucial. However, sourcing steel locally can minimize transportation emissions, making it an even greener choice.

Cost is a significant factor in construction. While steel framing might have a higher initial price, it ensures durability and longevity. Maintenance costs are lower compared to wood. Steel’s resistance to pests and weather can save money over time. Some projects may face challenges due to steel's thermal conductivity. Insulation becomes essential in such cases.

Tip: Always consider your local climate. This can impact energy efficiency and overall costs. Collaborating with local suppliers may also yield better material prices. Keep an eye on future maintenance needs. Reflect on whether your project aligns with sustainability goals. Balancing costs and environmental impact is key in today’s construction landscape.

Related Posts

-

Why Steel Structure Buildings Are the Future of Sustainable Construction

-

Top 10 Steel Outbuilding Ideas for Your Perfect Outdoor Space

-

2026 How to Choose the Best Red Iron Building Kits for Your Project?

-

How to Choose the Right Steel Building: Key Factors with 30% Cost Reduction Insights

-

10 Essential Tips for Optimizing Your Pemb Building Projects with Data-Driven Success

-

How to Choose the Best Steel Building Kits for Your Next Project

Getting the Most Out of Your Metal Building

Getting the Most Out of Your Metal Building Newsletter September 2025

Newsletter September 2025 Construction Benefits to Know About the One Big Beautiful Bill Act

Construction Benefits to Know About the One Big Beautiful Bill Act Unexpected Uses for Metal Buildings You Might Not Have Thought Of

Unexpected Uses for Metal Buildings You Might Not Have Thought Of The Most Common Metal Building Misconceptions We Hear (Part 2)

The Most Common Metal Building Misconceptions We Hear (Part 2) Vulcan Steel Structures Marks 40 Years of Innovation and Growth in Metal Building Manufacturing

Vulcan Steel Structures Marks 40 Years of Innovation and Growth in Metal Building Manufacturing